Table of Contents

- 1 The Role of Adhesives in Manufacturing

- 2 Types of Industrial Adhesives Used Today

- 3 Factors to Consider When Selecting an Adhesive

- 4 Environmental and Sustainability Considerations

- 5 Application Methods and Best Practices

- 6 Recent Advances in Adhesive Technology

- 7 Testing and Quality Assurance

- 8 Common Mistakes and How to Avoid Them

- 9 Future Trends in Industrial Adhesives

- 10 Summary: Making Informed Adhesive Choices

The Role of Adhesives in Manufacturing

Industrial adhesives have revolutionized how products are assembled, playing a pivotal role across automotive, aerospace, electronics, and construction sectors. Their ability to bond diverse materials and create lighter, more efficient components has increased adoption over traditional joining methods such as welding, riveting, and mechanical fasteners. Compared to mechanical approaches, adhesives offer superior stress distribution, improved aesthetics with seamless bonding, and the ability to join dissimilar materials without causing distortion or damage.

For manufacturers seeking to enhance product performance and streamline assembly processes, leveraging resources like Leechadhesives.com can make a significant difference. Access to the latest adhesive technologies and expert advice enables manufacturers to address current production needs and emerging challenges.

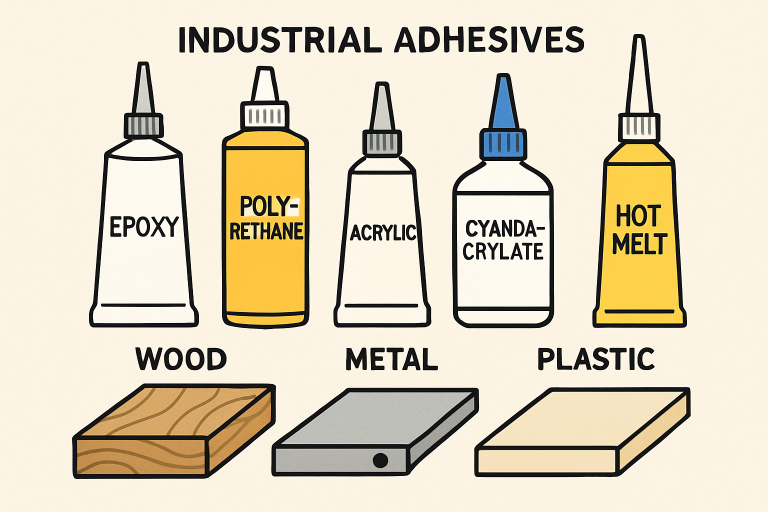

Types of Industrial Adhesives Used Today

A broad selection of industrial adhesives is available to meet diverse manufacturing needs. Common types include epoxy, polyurethane, acrylic, cyanoacrylate, and hot melt adhesives. Each has unique properties that make it suitable for specific applications:

- Epoxy: Known for high strength and chemical resistance; ideal for automotive, aerospace, and heavy machinery.

- Polyurethane: Highly flexible and resilient, with versatility for bonding wood, plastic, and metal surfaces.

- Acrylic: Offers fast cure times, good weather resistance, and strong bonds to plastics and metals.

- Cyanoacrylate: Fast-acting, best for small-scale bonding of rubber, plastics, and metals.

- Hot Melt: Quickly bonds porous and non-porous materials, often used in packaging and product assembly.

Choosing the right adhesive starts with understanding the intended use and the substrates involved. Manufacturers must assess both processing requirements and end-product conditions.

Factors to Consider When Selecting an Adhesive

Proper adhesive selection requires balancing multiple criteria. Substrate compatibility is crucial—an adhesive optimized for wood may fail on metal or plastic. Other key factors include cure time (the period needed for the adhesive to reach full strength), bonding strength and flexibility, and resistance to temperature extremes, chemicals, or moisture. For example, automotive components exposed to heat and vibration benefit from high-strength, flexible adhesives, while electronics may require quick-curing, non-conductive bonds.

Case studies frequently illustrate how the wrong adhesive can cause costly failures or recalls. Manufacturers must perform compatibility tests when joining dissimilar materials, such as metals to composites, to ensure the adhesive provides adequate bond strength throughout the product’s lifecycle.

Environmental and Sustainability Considerations

With mounting concerns about environmental impact, manufacturers are seeking eco-friendly adhesives made from renewable resources or designed for easy recycling. The global push for sustainable production has led to stricter regulations on using hazardous substances in adhesives. Responding to consumer demand and regulatory pressures, many industry leaders prioritize non-toxic formulations and recyclable materials.

Sustainability is also shaping research and development. As discussed in Nature’s recent exploration of industrial sustainability trends, adopting greener adhesives is crucial for future-leading manufacturers.

Application Methods and Best Practices

The efficiency and reliability of an adhesive bond depend heavily on the application method. Techniques include manual, automated, spray, bead, and film application, each tailored to specific production speeds and part geometries. Manufacturers need vigilant surface preparation for optimal results—cleaning and pre-treating surfaces ensures the best possible adhesion. Controlled curing, whether at ambient or elevated temperatures, is equally essential for developing full bond strength.

Quality control processes, such as visual inspections and periodic testing, detect inconsistencies early. Following best practices during preparation and application directly reduces the chances of costly rework or product failure.

Recent Advances in Adhesive Technology

Research and innovation are introducing adhesives with better performance and expanded application potential. New chemistries, such as structural acrylics with enhanced durability or epoxies for low-temperature cures, are driving the industry forward. Advances enable manufacturers to improve productivity, shorten assembly cycles, and meet demanding strength or sustainability targets.

For instance, Forbes reports that innovative adhesives enable lightweight vehicle designs and improved crash safety in the automotive sector. At the same time, aerospace manufacturers harness cleaner chemistries to reduce weight and environmental impact.

Testing and Quality Assurance

Thorough testing is essential before implementing any adhesive on a full scale. Standardized tests—such as lap shear, peel strength, and environmental resistance—help manufacturers gauge performance under real-world conditions. Continuous quality assurance ensures that each batch and application maintains the required bond durability and reliability standards. Small formulation changes or process variations could have costly consequences downstream without rigorous testing.

Common Mistakes and How to Avoid Them

Many manufacturing issues trace back to improper adhesive selection or application. Common mistakes include overlooking substrate compatibility, disregarding environmental exposure, and inconsistent surface preparation. Skipping recommended cure times or misapplying adhesive quantities can compromise bond integrity. Manufacturers are best served by consulting supplier technical data, maintaining strict process controls, and implementing regular staff training to mitigate these risks.

When problems do arise, troubleshooting typically involves reviewing the entire bonding process, from material storage and surface prep to curing and inspection, and identifying where deviations have occurred.

Future Trends in Industrial Adhesives

The next decade promises significant changes in adhesive technologies. Innovative adhesives with built-in sensors for monitoring bond integrity, formulations engineered for additive manufacturing, and developments driven by green chemistry are all on the horizon. As sustainability becomes increasingly central, expect a surge in bio-derived adhesives and chemically recyclable formulations tailored for circular manufacturing models.

Summary: Making Informed Adhesive Choices

The right industrial adhesive is critical for product performance, longevity, and sustainability. Manufacturers can optimize outcomes by thoroughly evaluating materials, application methods, and environmental demands; investing in robust testing protocols; and staying current with industry advances. Consulting trusted resources provides access to technical expertise and the latest product innovations, supporting manufacturers in making decisions that yield superior performance and competitive advantage.