Table of Contents

Introduction

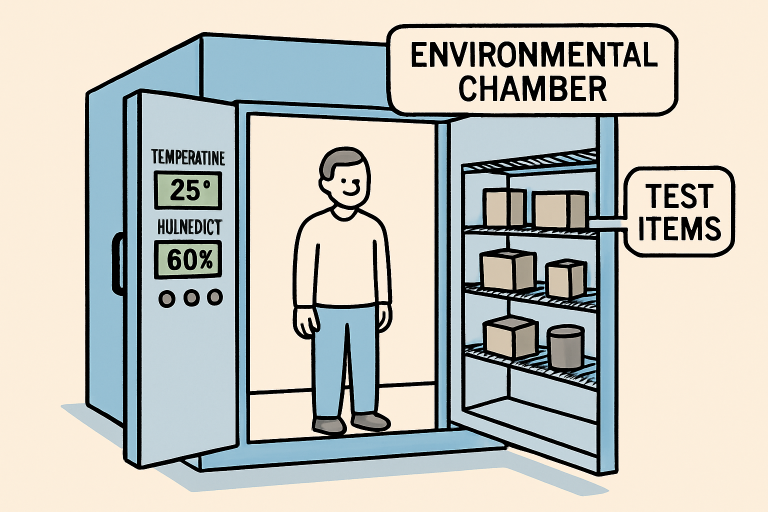

The capacity to reproduce and regulate precise environmental conditions is fundamental to breakthrough research and the successful development of new products. Modern research facilities increasingly rely on specialized tools to achieve this, and none is more valuable than a walk in temperature chamber. These innovative systems enable laboratories and R&D teams to mimic various climatic circumstances, from deep freeze to tropical humidity, within a controlled, repeatable environment.

With greater expectations for product reliability and regulatory standards, researchers must recreate real-world extremes in a controlled setting. Walk-in environmental chambers are indispensable for this purpose, allowing for testing materials, components, and finished products under conditions that would otherwise be challenging—or impossible—to replicate.

This level of control accelerates time to market and supports risk mitigation in a world where failure in the field can have significant consequences. By supporting batch testing and large-volume sample evaluations, these chambers improve test accuracy and optimize workflows and throughput for busy facilities.

Integrating walk-in environmental chambers helps organizations meet the increasing demands for compliance and sustainability. Facilities can efficiently simulate different storage and operational scenarios, ensuring immediate data needs and long-term product viability are met.

Precision in Environmental Control

Walk-in environmental chambers are celebrated for their remarkable ability to deliver consistent, precise control over temperature and humidity. Uniform ecological conditions throughout the chamber are essential for obtaining accurate, repeatable results, as even minor variances can undermine entire testing protocols. Advanced sensors and robust control systems work together to safeguard against fluctuations, allowing researchers to manipulate environmental parameters with remarkable accuracy. According to Scientific American, the credibility of experimental data is closely tied to this level of laboratory consistency.

Where traditional benchtop chambers fall short, walk-in units thrive by providing the space necessary for simultaneously testing large equipment, complete assemblies, or sizable product batches. This attribute is especially valuable within sectors such as aerospace, automotive, and defense, where everything from entire vehicle prototypes to multi-component systems must be examined. For example, automotive engineers can measure how complete vehicles respond to temperature ranges from -30°C to +70°C, anticipating challenges that may arise for consumers across global markets.

Versatility Across Industries

The adaptability of walk-in environmental chambers means their use is widespread and not limited to one corner of the research world. Whether it’s simulating years of shelf life for pharmaceuticals, validating the resilience of circuit boards, or confirming the safety of packaged foods, these chambers serve numerous vital industries:

- Pharmaceuticals: Critical for stability testing, confirming medication safety and efficacy across diverse climates and transport conditions.

- Electronics: Used to expose devices to repeated temperature cycling and humidity shifts, ensuring function and longevity.

- Food and Beverage: Validates that packaging and ingredients withstand inconsistencies in the supply chain storage.

This broad applicability demonstrates the walk-in chambers’ ability to bridge R&D requirements and evolving industry standards.

Advanced Features Enhancing Functionality

Contemporary walk-in environmental chambers deliver far more than mere temperature and humidity regulation. Rapid cycling between different setpoints facilitates accelerated stress testing—an invaluable tool when lifespan or durability under fluctuating environments must be known quickly. Additionally, the interior spaces are highly customizable, with modular fixtures and adjustable shelving that empower researchers to tailor space and setup to each experimental need. Advanced controllers with remote monitoring, programmable environmental profiles, and automated data logging increase productivity while reducing the risk of manual error.

Energy Efficiency and Sustainability

Energy use in research facilities is under increasing scrutiny due to economic and environmental pressures. Leading walk-in chamber models incorporate energy-saving technologies such as variable speed compressors, energy-efficient insulation, and low Global Warming Potential (GWP) refrigerants. Adopting these solutions aligns with global best practices for laboratory sustainability and helps organizations comply with emerging regulatory expectations around green laboratory operation. According to Nature, such sustainability practices are central to modern laboratory management.

Compliance with Regulatory Standards

The credibility of research outcomes depends heavily on strict adherence to recognized global and industry-specific standards. In this context, walk-in environmental chambers play a vital role by providing controlled testing environments that meet compliance requirements such as ISO, ASTM, and IEC. These standards are essential for industries where safety, quality, and reliability are non-negotiable, including pharmaceuticals, electronics, and product safety testing. For example, pharmaceutical labs rely on compliance to validate drug stability, while electronics manufacturers depend on it to ensure reliability under varying conditions. By investing in test chambers built to meet or exceed these requirements, organizations strengthen the accuracy and integrity of their data and gain greater confidence in regulatory acceptance. This alignment with standards helps streamline the approval process, reducing costly delays. It enables products to enter international markets faster, giving businesses a competitive edge in today’s globalized and highly regulated environment.

Conclusion

Walk-in environmental chambers have become indispensable tools for organizations committed to achieving reliable testing outcomes, operational efficiency, and full regulatory compliance. Designed with expansive and adaptable interiors, these chambers allow for testing small components and large-scale systems under tightly controlled environmental conditions. Their advanced technology enables precise regulation of temperature, humidity, and other variables, ensuring highly accurate and repeatable results. This makes them particularly valuable for research and development across scientific, industrial, and manufacturing sectors where consistency is critical. Additionally, their customizable design allows institutions to tailor configurations to unique project needs, maximizing usability and performance. As industries increasingly prioritize realism in testing scenarios, sustainability in processes, and scalability to meet growing demands, walk-in environmental chambers will continue to gain prominence. They are a cornerstone for ensuring safety, driving innovation, and maintaining quality standards that benefit businesses and their communities.